Drinks from Soviet times. Vodka traditions

Back in the 30s, the domestic vodka industry produced only four types of vodka: “40%”, “50%”, “56%” and “Special Moscow”. The first of those named was considered vodka normal quality, the rest - increased. In the production of "40%" vodka, rectified alcohol was used, produced from potatoes, grain or molasses. Vodkas “Special Moscow”, “50%” and “56%” were prepared from double rectified alcohol of increased quality. The use of alcohol from molasses for the preparation of these vodkas was not allowed. The alcohol was diluted with corrected river water, while the content of vodka was minerals could not exceed 500 mg, of which alkaline - no more than 300 mg .

The guaranteed shelf life of vodka made it possible to steal alcohol on a large and especially large scale.

In the post-war period, along with those previously mentioned, they began to produce Stolichnaya vodka and 95% drinking alcohol. As before, vodkas “40%”, “50%” and “56%” were a mixture of only alcohol with corrected water, treated with charcoal and filtered. When making Stolichnaya vodka, 20 g of sugar was dissolved in 1 dal of sorting, and Moskovskaya special 40% vodka was used with baking soda and acetic acid.

Drinking alcohol was a mixture of rectified ethyl alcohol produced from grain and potatoes with softened water. After mixing alcohol with water, the solution was filtered and aged; treatment with active carbon was not performed.

Regulatory requirements of that time for the physical and chemical parameters of vodka and drinking alcohol are given in table. 56.

Over time, the range of vodkas expanded significantly, and new regulatory requirements were introduced for previously produced ones. The following names of vodka were produced: “Vodka” (OST 18-7-76): “40%” (GOST 12714-67); "50%" and "56%" (GOST 12712-67); “Russkaya”, “Extra”, “Starorusskaya vodka”, “Wheat”, “Sibirskaya”, “Stolichnaya”, “Moscow special”, “Posolskaya”, “Golden Ring”, “Golden Gate” - all according to GOST 12712-80 and in limited quantities special vodkas: “Ukrainian Vodka”, “Novaya”, “Dzidrais”, “Crystal - Dzidrais”, “Viru-Valge”, “Lietuvishke skydrion” (“Lithuanian transparent”), “Festive”.

Alcohol. According to GOST 12712-80, only ethyl alcohol should be used for preparing vodkas and special vodkas

ІTable 56. Requirements for physical and chemical parameters of vodka and drinking alcohol - see link

Rectified, highly purified, “Extra” or “Lux”, produced from food raw materials in accordance with GOST 5962-67 (see Table 41). The type of alcohol used to prepare this or that vodka is given in table. 57. Vodkas for export are prepared only from “Extra” or “Lux” alcohol, produced from grain in a healthy state.

Water. The quality of water, which, for example, is over 60 wt.% in 40° vodka, plays an extremely important role. In the USSR, only natural, mainly river water was used to prepare vodka.

Natural water taken from one source or another always contains impurities of various substances in a dissolved and suspended state. These impurities are transferred to water as it moves across the surface and through soil layers, as well as during the formation and movement of clouds.

Substances dissolved in water are represented by: salts of mineral origin - calcium, magnesium, iron, potassium, sodium, manganese, copper; substances and salts of organic origin - these are mainly decomposition products of animal remains and flora; human production activities - mineral and organic fertilizers, components of wastewater treatment and emissions from industrial enterprises.

Suspended substances are represented by tiny particles of mineral and organic origin, colloids and microorganisms.

The amount of these impurities in water depends on the composition of the soil through which it moves, human production activities, and can vary significantly throughout the year. This is especially true for river, lake and well water during snow melt and floods. All impurities affect the organoleptic properties and physicochemical parameters of water and, depending on their content, it can be hard or soft, salty or fresh, cloudy or transparent, colored or colorless, and have one or another odor.

The hardness of water is determined by the calcium and magnesium salts present in it. As their content increases, water hardness increases. Water hardness is expressed in milligram equivalents - ribbons of calcium or magnesium ions per 1 liter (1 dm) of water (mg-eq/l); (mg-eq/dm). A hardness of 1 mEq/l corresponds to the content of 20.04 mg of Ca ions or 12.16 mg of Mg ions in water. Sometimes they use the old expression of hardness - in German degrees: 1 German degree of hardness corresponds to the content of 10 mg of CaO in water, that is, 1 mEq is equal to 2.004.

Water hardness is characterized by: a) general hardness; b) temporary or removable rigidity; c) constant rigidity. In this case, the total stiffness is the sum of temporary and permanent stiffness.

Temporary or removable hardness is caused by carbon dioxide salts of calcium and magnesium. When water boils, these salts precipitate.

Constant hardness is caused by sulfate and chloride salts of calcium and magnesium, which do not precipitate when water boils.

In the majority of cases, vodka factories use drinking water from public water supply systems and are located in large industrial centers, where the water is especially contaminated with human waste products. Drinking water (GOST 2814-73) meets a number of sanitary and epidemiological requirements that ensure its satisfactory organoleptic properties. It is harmless in terms of chemical and radiation composition and safe from an epidemiological point of view. However, the requirements for water used to prepare vodka are significantly higher. In particular, natural drinking unsoftened water should have a hardness of no higher than 1 mEq/dm, softened and desalted water - up to 0.36 mEq/dm (according to GOST 12712-80). For vodkas going for export, these requirements are even more stringent: natural drinking unsoftened water must have a hardness of no higher than 1 mEq/dm; corrected, including softened, hardness must be up to 0.1 mEq/dm (according to GOST 27907-88). The total content of mineral salts in water should not exceed 0.5 g. Therefore, to ensure the necessary salt composition, transparency, crystal luster and odorlessness, drinking water is treated before mixing with alcohol: softened, decolorized, deodorized, filtered. This treatment is carried out on the basis of laboratory water tests and in each specific case includes different technological steps and quantities of chemicals used.

Sometimes water is almost completely demineralized (desalted), as a result of which its properties become close to those of distilled water. Note that in the USSR distilled water was not used to prepare vodka: vodka prepared using it has an “empty” taste.

Coal sorting processing. Since the 1930s in the USSR, sorting has been processed only with active carbon. At the same time, the duration of its contact with sorting and dosage, in comparison with charcoal, were significantly reduced, since based on analytical studies and tasting it was found that the duration of contact of the sorting with active carbon should not exceed 30 minutes. Beyond this time, the taste of vodka does not improve and, moreover, may deteriorate, since the content of aldehydes in it increases. It was believed that when processing the sorting for the specified time, 16 g of active carbon per 1 dal of sorting was sufficient. These figures were normatively fixed for “40%” vodka. In the case of preparing it from alcohol from molasses, 24 g of active carbon were consumed per 1 dal. For higher quality vodkas (“50%”, “56%” and “Special Moscow”), 30 g of active carbon was consumed per 1 dal of sorting, also with 30 minutes of contact between the coal and the sorting.

During the specified time, it is necessary to ensure continuous and vigorous mixing of the coal with the sorting, after which the sorting must be immediately separated from the coal.

Mostly birch activated carbon with particle sizes from 0.5 to 3.5 mm was used. The weight of 1 liter of coal must be at least 170 g.

At pre-war factories, three methods of processing sorting with active carbon were used: 1) Moscow; 2) Kyiv; 3) Tula.

Moscow way. Sorting is poured into a metal container, after which a weighed amount of coal is poured into it, based on regulatory documentation and sorting volume. Immediately after this, continuous and vigorous mixing of the sorting with coal is carried out, which is carried out with oars, a mechanical stirrer, or compressed air from a compressor. After 30 minutes, stirring is stopped, the coal is allowed to settle to the bottom of the container, which occurs within 4 hours, the sorting is drained, and the coal is sent for regeneration. Since in this technology the duration of contact between the sorting and coal actually exceeds 30 minutes, this was considered its significant drawback.

Kyiv method. In this method, the sorter is in contact with coal for exactly 30 minutes. This is achieved due to the fact that coal in the calculated quantity is not poured directly into the tank, but is introduced into it in drums made of metal mesh. In this case, the sorting is launched into a drum with coal, washes the coal contained in it and flows through the holes of the mesh into the tank. At the same time, the sorting tank is mixed with compressed air. After 30 minutes, the drum with coal is removed from the tank, the coal is sent for regeneration, and sorting is sent for filtration.

Tula method. This method used filters available on pre-revolutionary vodka factories, but the sorting moved from bottom to top, which ensured its vigorous mixing with coal.

In modern technologies, sorting processing, with certain differences, is carried out both according to the Tula and methods used at pre-revolutionary factories. Crushed active wood coal of BAU-A or DAK grades is used according to GOST 6217-74; when preparing vodka for export, BAU-A brand. (According to the aforementioned GOST, BAU-A grade coal is intended for use in distillery production and for adsorption from solutions and aqueous media; DAK grade coal is intended for purification of steam condensate from oil and other impurities.) Since the implementation of these technologies in living conditions difficult and impractical, we will not describe them. Let us only note that in detail modern technologies activated carbon sorting treatments are described in .

Filtering sorting. The sorting is filtered twice: before and after treatment with active carbon. Quartz sand is used as the main filter material, which at vodka production plants is divided into several fractions based on the size of the sand grains. After fractionation, the sand is thoroughly washed with water, then with 3% hydrochloric acid oh and again with water. The sand thus treated is loaded into cylindrical drums called sand filters. In the simplest sand drums of old designs (Fig. 46), sand fractions with particle sizes from 1 to 3 mm and from 3.5 to 5 mm and coarse gravel were used.

The filter was a copper cylinder, tinned inside, with a diameter of 0.7 m and a total height of 1 m. The total height of the filter layers was about 0.7 m. The number of filter layers was no more than Si. The cylinder was divided in height into three chambers using removable perforated diaphragms , also made of tinned copper: a) upper - supply; b) middle - boot; c) lower - team. The filter material is placed in the loading chamber in layers. In this case, the lower and upper layers are made of gravel, the intermediate layers are made of sand. The perforated diaphragms were covered with fabric pads made of overcoat cloth, felt or flannel. Sometimes layers of sand and gravel were also separated from each other by spacers made of these materials. To retain the largest particles, a pad of several layers of cotton wool was used, wrapped in gauze and placed in the upper part of the filter. Often, in order to retain the largest coal particles, preliminary

filtration of the sorting, passing it under pressure through a glass with a layer of flannel or cloth fixed at its bottom.

Direction of movement

Sorting while filtering from top to bottom. The first portions of the screening, passing through the freshly loaded sand and gravel, are cloudy, so they are sent back to the screening tank. When a crystal clear sorting filtrate begins to come out of the filter, switch the filter from the sorting tank to the finishing one. In the finishing vat, sorting vodka is refined to the required strength by adding alcohol or carefully filtered water, after which the vodka is bottled.

Modern filters use sand of three fractions with particle sizes: from 1 to 1.5 mm; from 1.5 to 2.0; from 2.0 to 3.0 mm. The fabric is not used by placing layers of sand with different particle sizes on top of each other. In this case, the bottom layer of sand, which has the largest grain sizes, is poured onto a fine-mesh metal mesh mounted on a durable lattice frame. Along with sand filters, monolithic ceramic filters with pore sizes of several tens of microns are used.

Vodka recipes.

In a strict sense, vodka should consist only of water and rectified bread ethyl alcohol with the latter's share of 40 vol.%. Even before World War II, no other ingredients, with the exception of baking soda, were allowed in its production. According to the regulatory documentation of that time, the content of alkaline substances in terms of drinking soda or vodka of ordinary quality could not exceed 300 mg, due to which it was allowed to add baking soda to the sorting with the missing alkalinity, thereby bringing the alkalinity to the full norm (300 mg/l) . For vodkas of improved quality, alkalinity was allowed to be increased to 600 mg/l. Due to the fact that in an alkaline environment the absorption properties of activated carbon are weakened, it was recommended to add soda after treating the sorting with carbon.

Vodka produced in the USSR

Along with this, several more vodka recipes are given in the scientific and technical literature of that time. In particular, in the Technical Encyclopedia, vol. 3, p. 860 - 862, (M.: Sov. encycl., 1928) when preparing vodka, it is recommended to add 0.3 g of baking soda and 1.6 g of beet sugar, which leads to a softening of the harshness of its taste. According to vodka high taste qualities is obtained if to each liter of sorting we add 25 mg of potassium permanganate, previously dissolved in small quantity water, and 40 mg of 80% acetic acid.

After half an hour, add 200 mg of baking soda and leave everything for 1 - 2 days, after which the entire mixture is filtered from manganese dioxide. The oxidative effect of potassium permanganate carries with it, like ozone, a certain aging effect. After filtering already in finished product manganese is absent.

In the post-war period, the range of substances used in the production of vodka expanded significantly.

Thus, according to GOST 12712-80, when preparing this or that type of vodka and special vodka, in addition to the previously mentioned alcohol, water and active carbon, the following are used: refined granulated sugar and refined sugar according to GOST 22-78, sodium bicarbonate (baking soda) according to GOST 2156-76; food grade acetic acid according to GOST 6968-76; food grade citric acid according to GOST 908-79; edible lactic acid according to GOST 490-79; hydrochloric acid according to GOST 3118-77; potassium permanganate according to GOST 20490-75; table salt according to GOST 13830-68; distilled glycerin according to GOST 68224-76; natural honey according to GOST 19792-87; skimmed cow's milk powder according to GOST 10970-87; potato starch according to GOST 7699-78; aromatic alcohols, obtained from aromatic plant raw materials and highly purified rectified alcohol, essential oils and some other products. It is clear that some of the named substances, such as, for example, starch, milk and potassium permanganate, are used only for sorting cleaning and are absent from the vodka entering the trade.

Along with this, some vodkas, for example, "Pshenichnaya" and "Sibirskaya", are made only from alcohol and water and do not contain additives, with the exception of those that come from coal and are formed during the sorting process. Let us present the technology for adding additives and the recipes of some vodkas.

So, according to the recipe of A. S. Egorov and his colleagues, given in, high organoleptic indicators vodka contains 1 dal 36 mg of NaCl (table salt), 546 mg of NaHC03 (baking soda) and 50 mg of Ca(HCO3)2. According to this recipe, table salt and baking soda in the indicated quantities are added directly to the water, after which the solution is passed through a filter with marble chips. During the filtration process, part of the soda chemically interacts with the marble, resulting in the formation of Ca(HCO3)2. (Marble is a rock, its main component is calcite (CaCO3).) Marble chips with particle sizes of 10 - 20 mm are used. The indicated amount of Ca(HCO3)2 is formed during the duration of contact of the soda solution and table salt in water with marble chips for 10 - 20 minutes. Water treated in this way is used to dilute alcohol.

Recipes for vodkas “50%”, “Stolichnaya”, “Extra”, “Vodka”, “Moskovskaya special”, “Ukrainian vodka” and “Prazdnichnaya” are given on the basis of; "Sibirskaya" and "Pshenichnaya" - OST 18-292-76 and OST 18-296-76, respectively; "40%" -

GOST 12714-67, "56%" - GOST 12712-67.

Unfortunately, we cannot provide the recipes for other vodkas, since it has a prohibitive stamp on it, and the authors are law-abiding citizens.

Vodka "Stolichnaya" To prepare this vodka, refined granulated sugar is used. For 1 dal of sorting, 20 g of sugar is consumed, which is added to the sorting in the form of syrup.

IN industrial conditions sugar syrup prepared with a sugar content of 65.8 and 73.2 wt.%, which corresponds to approximately 0.52 and 0.37 liters of water per kilogram of sugar. The technology is carried out as follows. In a container of the required volume, heat the water to 50 - 60 ° C, after which, without stopping the heating, pour the calculated amount of sugar into it with constant stirring and, having completely dissolved it, bring the syrup to a boil.

During the boiling process, the heating is reduced or stopped several times and at this time the foam is removed from the surface of the syrup. The cessation of foam formation is a sign that the syrup is ready. After this, the heating is stopped and the syrup is quickly cooled. Heat treatment They try to process sugar syrup as quickly as possible, because the syrup turns yellow from a long stay at boiling temperature. “It should be noted that while the sugar syrup is boiling, it should be constantly stirred so that it does not burn or turn yellow.

The finished syrup is poured into clean, strong oak barrels or tinned metal utensils, in which it is left to cool. It is best to cook the syrup in a (copper) boiler with a steam jacket heated by steam; The inner surface of the boiler must be well tinned. It is also possible to heat the boiler with a steam coil. Steam heating is convenient because it is easier to regulate and reduces the risk of burning the syrup. If the plant has a fire furnace under the boiler for boiling syrup, the walls of the boiler must be protected from direct contact with the flame by installing safety shields or brickwork with an air gap, or used for heating water bath" .

Vodka "Extra". To prepare this vodka, refined granulated sugar and potassium permanganate are used. For one sorting dal, 25 g of sugar and up to 10 mg of potassium permanganate are consumed. To sort, first add a solution of potassium permanganate, mix, and then add sugar syrup.

Vodka "Vodka". To prepare this vodka, 1 dal of sorting requires 1 g of baking soda (IaHCO3), 0.308 g of baking soda citric acid and 10 g of refined granulated sugar. Baking soda injected directly into sorting in the form of an aqueous solution. Sugar is introduced into sorting in the form of invert sugar. From specified quantity 0.3 g of citric acid is added to the sorting in the form of a solution to create a certain acidity, and 0.008 g is used to obtain invert sugar (0.08% by weight of sugar).

Invert sugar is a mixture of equal parts

Glucose and fructose. It is obtained by heating sugar syrup in the presence of citric or hydrochloric acids. Sucrose under these conditions is inverted, that is, a sucrose molecule attaches a water molecule and breaks down into molecules of glucose and fructose: C12H22O11 + H20 = CbHigOb + CbHigOb. sucrose water glucose fructose

Compared to sucrose, invert sugar is less susceptible to crystallization when mixed with aqueous-alcohol solutions, is sweeter and has a larger total mass.

To prepare an invert sugar solution, first prepare sugar syrup at the rate of 1 kg of sugar per 0.52 liters of water using the previously described technology. Having removed the foam from the syrup for the last time, add a 10% aqueous solution of citric acid in the amount of 0.08% citric acid by weight of the processed sugar and, stirring, keep it at 95 - 100 ° C for 2 hours. During this time, about 50 % sucrose. With a longer heating duration and, accordingly, the degree of inversion, the syrup darkens, which is unacceptable in the production of vodka. The inversion is carried out in enamel containers.

Vodka "Moscow Special".

To prepare this<эдки используют пищевую соду и уксусную кислоту. Пищевую соду в виде концентрированного раствора ее в сортировке вносят непосредственно в основную порциию сортировки для придания ей мягкости, а также используют с уксусной кислотой для получения уксуснокислого натрия (СНзСОСЖа). В каждом конкретном случае массу соды, которую необходимо внести в сортировку, определяют путем титрования исходной сортировки в лаборатории и выполнения расчетов по формуле

M = (0.084 g/ml) (A2 - Ai), where M is the mass of chemically pure NaHC03, which must be added to each 1 dal of sorting to - ensure the necessary alkalinity; A2 is the required alkalinity of sorting, expressed in ml of 0.1 N HCL solution per 100 ml of sorting; A i is the initial alkalinity of the sort, in ml of 0.1 N HC1 solution per 100 ml of sort.

Example: Let Ai = 1.0 ml, and A2 = 3.0 ml (see Table 57 for the requirements for the alkalinity of Moskovskaya Special vodka). Thin M = 0.84 g/ml x (3.0 ml - 1.0 ml) = 1.68 g of baking soda per 1 dal of sorting. A weighed amount of soda is first thoroughly mixed with a small amount of sorting, then poured into the main portion of sorting and also mixed thoroughly.

Titration (determination of alkalinity) of sorting is carried out as follows. 100 ml of sorting is poured into a conical flask made of unpainted chemical-resistant glass with a capacity of 250 - 500 ml, two drops of methyl red solution are added to it, shaken, after which a 0.1 N HC1 solution is gradually added with constant shaking. The titration is completed when the color of the screen changes from yellow to pink. The number of milliliters of HC1 solution used for titration is a measure of the alkalinity of the sort.

Table 57. Requirements for physical and chemical parameters of vodka (see source)

Vodkas “40%”, “50%”, “56%”, “Sibirskaya” and “Wheat”.

To prepare these vodkas, only alcohol and water are used. At the same time, water for Sibirskaya and Pshenichnaya vodkas is treated with active carbon and filtered before mixing with alcohol.

Special vodka "Ukrainian vodka". To prepare this vodka, use 40 g of honey per dal of sorting. Preference is given to linden honey. Honey is introduced into sorting in the form of its solution in vodka or sorting, calculated at the rate of 1 g of honey per 10 ml of liquid. In order to remove mechanical particles and colloidal substances present in honey, before adding it to the sorting, the honey solution is carefully filtered through filter cardboard according to GOST 12290-89.

Special vodka "Festive". To prepare this vodka, use (from the calculation for 1 dal of sorting): baking soda - 2 g, sugar - 2 g, citric acid - 0.8 g.

Solutions of sugar, invert sugar, baking soda and potassium permanganate are added to the sorting before it is processed with active carbon; honey, glycerin, essential oils and aromatic alcohols after its treatment with active carbon, since the latter partially absorbs these substances.

Vodka quality. Determined organoleptically based on tasting and analytically through laboratory tests.

At the same time, the quality requirements for vodkas produced for domestic consumption are set by GOST 12712-80, for export - GOST 27907-88.

Organoleptic indicators of vodka are: a) appearance; b) color; c) taste and aroma. According to these GOSTs, the requirements for the organoleptic characteristics of vodkas produced for domestic consumption and exported are identical: vodka must be a transparent liquid without foreign inclusions or sediment; should be colorless; have the taste and aroma characteristic of this type of vodka, and do not have any foreign taste or aroma. In practice, organoleptic indicators are assessed on a ten-point scale. The highest score - 10 points is assigned to vodka that has impeccable transparency and crystal luster (2 points); not having a sweet, pungent or bitter taste (4 points); without the smell of alcohol and other foreign substances and with an aroma characteristic of vodka of this type (4 points).

Analytical (physical and chemical) requirements for vodkas produced for domestic consumption (GOST 12712-80) and for export (GOST 27907-88) are given in Table. 57.

Later, in GOST 12712-80, in accordance with change No. 4 of 07/04/86, in the table specifying the requirements for the physical and chemical parameters of vodka, the word “Extra” was excluded from the column “Norm for vodkas from highly purified alcohol”, and in In accordance with change No. 5 of November 12, 1991, the requirements for the physical and chemical characteristics of vodka are set out in a new edition (see Table 58).

Vodkas have a certain shelf life. According to GOST 12712-80, the guaranteed shelf life for vodka is 12 months, vodka intended for the USSR Ministry of Defense is 18 months, and special vodka is 6 months from the date of bottling.

(the guaranteed shelf life of vodka made it possible to steal alcohol on a large and especially large scale.

If, for example, a distillery “makes a mistake” with the date of release and puts last year’s date, then you can underfill the alcohol, and the strength will be lower than the guarantee, then refer to the fact that this batch of vodka “was lying in storage” - and everything will be fine! - note . my)

Vodka is a strong alcoholic beverage. (According to GOST 20001-74: liqueurs and vodka products are alcoholic drinks with a strength of 12 - 60%, prepared by mixing semi-finished products with rectified alcohol; strong liqueurs and vodka products are alcoholic drinks with a strength of 30% and above).

However, as we say in Kyiv, “Each drink has its own buzz.” Therefore, along with vodka, the industry produces other alcoholic drinks based on rectified ethyl alcohol: liqueurs, creams, liqueurs, tinctures, balms, etc. These drinks have different strengths (from 12 to 60 °), and, unlike vodka contains significant amounts of sugar, food coloring, acids, aromatic and other substances. The technologies for producing and formulating such drinks, as well as cognac, whiskey and gin, will be presented in the second part of this book.

There are no substances, including ethyl alcohol, with 100% content of the main component in nature, since any substance, even the purest, contains a certain amount of impurities. Therefore, for example, the terms “100% alcohol” or “100% acid” do not correspond to the real substance, but are used to facilitate calculations and records. The industry produces, in limited quantities, so-called absolute alcohol, containing at least 99.8 vol.% ethyl alcohol, and water as the main impurity. In laboratories, using certain chemicals, rectified and absolute alcohols produce alcohol with a negligible water content. In modern scientific and technical literature, instead of the term “100% alcohol,” the term “anhydrous alcohol” is more often used.

Detailed tables for converting metric units into Russian and Russian into metric are given in the “Encyclopedic Dictionary” (vol. 9) of Brockhaus-Efron. - St. Petersburg: TypogrAkts. Society "Publishing", Brockhaus-Efron, 1900.

In the original hereinafter - “swelling”.

In the original hereinafter “resolution”.

This corresponds to 1 kg of flour per 4.2 liters of water.

This corresponds to 1 kg of flour per 5.4 liters of water.

Baltic Provinces - German name for the Baltic region

Before the invention of alcohol meters, the alcohol content of wine was determined by burning off the alcohol. For this purpose, a certain volume of wine was placed in a metal glass and set on fire. It was believed that the difference in the volume of wine before and after the end of combustion corresponded to the volume of alcohol present in it. It is clear that this method was inaccurate and always gave an overestimated alcohol content, since part of the water evaporated during the combustion process. If the burnt-out alcohol was half or two-thirds of the volume, then in Russia such wine was called “polugar” or “two-thirds gar,” respectively.

Golden autumn, 1 rub. 15 kopecks. - “Zosya”

Vasisubani, 2 rub. 00 kopecks. - “To the bathhouse with Vasya”

Port wine 777, 3 rubles 40 kopecks. - “Three Axes”, “Lowing”

Bile mitzne, 1 rub. 70 kopecks. - "Biomitsin"

Import substitution, it turns out, was also relevant during the Soviet Union.

Vermouth, 1 rub. 50 kopecks - “Vera Mikhailovna”, “Vermouth”

Aroma of gardens, 1 rub. 80 kop. - “The aroma of butts”

Autumn garden, 1 rub. 70 kopecks - “Fruit-profitable”

Port wine 33.2 rub. 15 kopecks - “33 misfortunes”

Rkatsiteli, 2 rubles. 50 kopecks - “Cancer to the goal”

Caucasus, 2 rubles 50 kopecks. - "Beggar in the Mountains"

Anapa, 2 rub. 30 kopecks. - "Sunstroke"

Fruit wine, 1 rub. 30 kopecks. - “Tears of Michurin”

The most legendary "babble" of the USSR

Port wine “AGDAM”, alcohol 19 vol.%, price 2 rubles. 60 kopecks, - as soon as they were called - “As I will give”, “Agdam Bukharyan”, “Agdam Zaduryan”, etc., etc.

This hellish mixture of fermented grape juice, sugar and potato alcohol was drunk by everyone in the country of victorious socialism - workers, students, academics.

Agdamych completed his victorious march across the expanses of the country only in the 90s after the destruction of the cognac factory in the town of Agdam - the most famous city of Azerbaijan, which is now completely wiped off the face of the earth as a result of the Karabakh conflict.

At the request of workers in the alcohol field:

Dessert drink “Volga Dawns”, strength 12% vol., sugar 24%, price - 1 rub. 15 kopecks. - a glorious representative of the Soviet “shmurdyaks”.

As a rule, this “dessert” was tried only once, because... the second time, the urge to vomit began just from the mere mention.

“Tincture of natural herbs with tonic properties” is the long name on the label of another legendary drink of the 70s - Abu Simbel Balsam.

Capacity 0.83 l., strength 30 degrees, price - 5 rubles. 80 kop.

As experienced senior students enlightened us, elementary students: “Abu” is the best “butterfly handler.”

The cork, they taught, must be opened very carefully so as not to damage it, and the bottle must not be thrown away under any circumstances: after emptying, you must pour regular port wine into it, carefully cork it, and everything is ready for the next romantic date!

Well, and finally, one of the main “gifts” from N.S. Khrushchev to the Soviet people - the wine of Algeria, which, with the light hand of domestic “winemakers”, turned into “Solntsedar”, “Algerian” and “Rose Vermouth”.

The people who survived, having tasted this muck, dubbed it “ink”, “fence paint”, “bug pest”, etc., etc., but nevertheless, almost 5 million decalitres of this swill came to the Union by tankers, which with difficulty steamed after draining in the village of Solntsedar near Gelendzhik.

It was all about the price: “Algerian” - 14% and 65 kopecks!!!, “Solntsedar” - 20% and 1 rub. 25 kopecks!

“Solntsedar”, which became a symbol of the era of stagnation, collected its deadly harvest in the vastness of the USSR until 1985, when Gorbachev, who went down in the history of the country’s wine consumption as the Mineral Secretary, began his fight against drunkenness and alcoholism.

"Moscow special vodka"

0.5 l, 40%, price 60 rub. 10 kopecks,

Dishes 50 kopecks, cork 5 kopecks. 1944 - “Bitch”

“Vodka” 0.5 l, 40%, price 3 rubles. 62 kop.

1970 - “Crankshaft”

“Vodka” 0.5 l, 40%, price 4 rubles 70 kopecks.

1982 - “Andropovka”,

aka, “First-Grader” (released in early September),

aka, “Yurka’s Dawns” (based on the film)

“Vodka “Russian” 0.33l, 40%,

I don’t remember the price, in a Pepsi bottle - “Raiska”

(in honor of the wife of the “Mineral Secretary of the CPSU” Gorbachev)

“Vodka “Russian” 0.1 l, 40% - “Bum Yogurt”

Vodka “Krepkaya-Strong”, 0.5 l, strength 56%.

This very rare vodka from the USSR period, 56% alcohol, is deprived of popular attention, because... sold mainly to foreigners.

The legend about its appearance is connected with the name of Stalin: they say, the leader, who had a weakness for polar explorers, asked them at one of the receptions what they drink during the winter, to which they answered: alcohol diluted to the strength of the parallel at which they at the moment of consumption, they are at the Pole - 90%, Salekhard - 72%, etc., and already at the next Kremlin reception on the occasion of the award, Stalin treated the conquerors of the North with specially prepared vodka with a strength of 56%, which corresponded to the geographical latitude of Moscow.

Pepper is not only for colds!

“And we walked together, like on a cloud,

And we came to Beijing hand in hand,

She drank Durso, and I drank Pepper.

For the Soviet family, exemplary!”

After these lines from Alexander Galich, I simply don’t want to comment tritely on this one of the most popular tinctures of the USSR, therefore, just facts from the labels:

Bitters tincture “Pepper”, 0.5 l, 1991,

35%, price with the cost of dishes 8 rubles. 00 kopecks.

“Ukrainian gorilka with pepper”, 0.7 l, 1961,

40%, price with the cost of dishes 4 rubles. 40 kopecks

There was also a tincture of “Pepper” in the USSR, 30%, produced already since 1932, but for more than 30 years of collecting, I never came across a single bottle of it, because it was not just an infusion of different varieties of allspice and the first a remedy for colds, but also a real holiday for all drinking citizens of the country of the Soviets.

According to GOST 12712-80, depending on the taste and aromatic properties, YYKR are divided into vodka and special vodka. According to GOST 20 001-74, vodka is an alcoholic drink obtained by sorting with active carbon followed by filtration; Special vodka is high-grade vodka with a strength of 40 - 45% with a distinctly specific aroma and mild taste.

Back in the 30s, the domestic vodka industry produced only four types of vodka: “40%”, “50%”, “56%” and “Special Moscow”. The first of those named was considered vodka of regular quality, the rest - high quality. In the production of "40%" vodka, rectified alcohol was used, produced from potatoes, grain or molasses. Vodkas “Special Moscow”, “50%” and “56%” were prepared from double rectified alcohol of increased quality. The use of alcohol from molasses for the preparation of these vodkas was not allowed. The alcohol was diluted with corrected river water, while in vodka the content of mineral substances could not exceed 500 mg, of which alkaline substances - no more than 300 mg.

In the post-war period, along with those previously mentioned, they began to produce Stolichnaya vodka and 95% drinking alcohol. As before, vodkas “40%”, “50%” and “56%” were a mixture of only alcohol with corrected water, treated with charcoal and filtered. When making Stolichnaya vodka, 20 g of sugar was dissolved in 1 dal of sorting, and Moskovskaya special 40% vodka was used with baking soda and acetic acid.

Drinking alcohol was a mixture of rectified ethyl alcohol produced from grain and potatoes with softened water. After mixing alcohol with water, the solution was filtered and aged; treatment with active carbon was not performed.

The regulatory requirements of that time for the physical and chemical parameters of vodka and drinking alcohol are given in table. 56.

Over time, the range of vodkas expanded significantly, and new regulatory requirements were introduced for previously produced ones. The following names of vodka were produced: “Vodka” (OST 18-7-76): “40%” (GOST 12714-67); "50%" and "56%" (GOST 12712-67); “Russian”, “Extra”, “Starorusskaya vodka”, “Wheat”, “Sibirskaya”, “Stolichnaya”, “Moscow special”, “Posolskaya”, “Golden Ring”, “Golden Gate” - all according to GOST 12712-80 and in limited quantities special vodkas: “Ukrainian Vodka”, “Novaya”, “Dzidrais”, “Crystal - Dzidrais”, “Viru-Valge”, “Lietuvishke skydrion” (“Lithuanian transparent”), “Festive”.

Alcohol. According to GOST 12712-80, only ethyl alcohol should be used for preparing vodkas and special vodkas

|

ІTable 56. Requirements for physical and chemical parameters of vodka and drinking alcohol |

Rectified, highly purified, “Extra” or “Lux”, produced from food raw materials in accordance with GOST 5962-67 (see Table 41). The type of alcohol used to prepare this or that vodka is given in table. 57. Vodkas for export are prepared only from “Extra” or “Lux” alcohol, produced from grain in a healthy state.

Water. The quality of water, which, for example, is over 60 wt.% in 40° vodka, plays an extremely important role. In the USSR, only natural, mainly river water was used to prepare vodka.

Natural water taken from one source or another always contains impurities of various substances in a dissolved and suspended state. These impurities are transferred to water as it moves across the surface and through soil layers, as well as during the formation and movement of clouds.

Substances dissolved in water are represented by: salts of mineral origin - calcium, magnesium, iron, potassium, sodium, manganese, copper; substances and salts of organic origin - mainly these are decay products of the remains of animal and plant life; human production activity - mineral and organic fertilizers, components of waste water and emissions from industrial enterprises.

Suspended substances are represented by tiny particles of mineral and organic origin, colloids and microorganisms.

The amount of these impurities in water depends on the composition of the soils through which it moves, human production activities, and can change significantly throughout the year. This is especially true for river, lake and well water during snow melt and floods. All impurities affect the organoleptic properties and physicochemical parameters of water and, depending on their content, it can be hard or soft, salty or fresh, cloudy or transparent, colored or colorless, and have one or another odor.

The hardness of water is determined by the calcium and magnesium salts present in it. As their content increases, water hardness increases. Water hardness is expressed in milligram equivalents - ribbons of calcium or magnesium ions per 1 liter (1 dm) of water (mg-eq/l); (mg-eq/dm). A hardness of 1 mEq/l corresponds to the content of 20.04 mg of Ca ions or 12.16 mg of Mg ions in water. Sometimes they use the old expression of hardness - in German degrees: 1 German degree of hardness corresponds to the content of 10 mg of CaO in water, that is, 1 mEq is equal to 2.004.

Water hardness is characterized by: a) general hardness; b) temporary or removable rigidity; c) constant rigidity. In this case, the total stiffness is the sum of temporary and permanent stiffness.

Temporary or removable hardness is caused by calcium and magnesium carbonate salts. When water boils, these salts precipitate.

Constant hardness is caused by sulfate and chloride salts of calcium and magnesium, which do not precipitate when water boils.

In the majority of cases, vodka factories use drinking water from public water supply systems and are located in large industrial centers, where the water is especially contaminated with human waste products. Drinking water (GOST 2814-73) meets a number of sanitary and epidemiological requirements that ensure its satisfactory organoleptic properties. It is harmless in terms of chemical and radiation composition and is safe from an epidemiological point of view. However, the requirements for water used to prepare vodka are significantly higher. In particular, natural drinking unsoftened water should have a hardness of no higher than 1 mEq/dm, softened and desalted water - up to 0.36 mEq/dm (according to GOST 12712-80). For vodkas going for export, these requirements are even more stringent: natural drinking unsoftened water must have a hardness of no higher than 1 mEq/dm, corrected, including softened, up to 0.1 mEq/dm (according to GOST 27907- 88). The total content of mineral salts in water should not exceed 0.5 g. Therefore, to ensure the necessary salt composition, transparency, crystal luster and odorlessness, drinking water is subjected to treatment before mixing with alcohol: softened, decolorized, deodorized, filtered. Such treatment is carried out on the basis of laboratory tests of water and in each specific case includes various technological operations and quantities of chemicals used.

Sometimes water is almost completely demineralized (desalted), as a result of which its properties become close to those of distilled water. Note that in the USSR distilled water was not used to prepare vodka: vodka prepared using it has an “empty” taste.

Coal sorting processing. Since the 1930s in the USSR, sorting has been processed only with active carbon. At the same time, the duration of its contact with the sorting and the dosage, in comparison with charcoal, were significantly reduced, since, based on analytical studies and tasting, it was established that the duration of contact of the sorting with active carbon should not exceed 30 minutes. Beyond this time, the taste of vodka does not improve and, moreover, may deteriorate, since the content of aldehydes in it increases. It was believed that when processing the sorting for the specified time, 16 g of active carbon per 1 dal of sorting was sufficient. These figures were normatively fixed for “40%” vodka. In the case of preparing it from alcohol from molasses, 24 g of active carbon were consumed per 1 dal. For higher quality vodkas (“50%”, “56%” and “Special Moscow”), 30 g of active carbon was consumed per 1 dal of sorting, also with 30 minutes of contact between the coal and the sorting.

During the specified time, it is necessary to ensure continuous and vigorous mixing of the coal with the sorting, after which the sorting must be immediately separated from the coal.

Mostly birch activated carbon with particle sizes from 0.5 to 3.5 mm was used. The weight of 1 liter of coal must be at least 170 g.

At pre-war factories, three methods of processing sorting with active carbon were used: 1) Moscow; 2) Kyiv; 3) Tula.

Moscow way. Sorting is poured into a metal container, after which a weighed amount of coal is poured into it, based on regulatory documentation and the volume of sorting. Immediately after this, continuous and vigorous mixing of the sorting with coal is carried out, which is carried out with oars, a mechanical stirrer, or compressed air from a compressor. After 30 minutes, stirring is stopped, the coal is allowed to settle to the bottom of the container, which occurs within 4 hours, the sorting is drained, and the coal is sent for regeneration. Since in this technology the duration of contact between the sorting and coal actually exceeds 30 minutes, this was considered its significant drawback.

Kyiv method. In this method, the sorter is in contact with coal for exactly 30 minutes. This is achieved due to the fact that the calculated amount of coal is not poured directly into the tank, but is introduced into it in drums made of metal mesh. In this case, the sorting is launched into a drum with coal, washes the coal contained in it and flows through the holes of the mesh into the tank. At the same time, the sorting tank is mixed with compressed air. After 30 minutes, the drum with coal is removed from the tank, the coal is sent for regeneration, and sorting is sent for filtration.

Tula method. This method used filters available at pre-revolutionary vodka factories, but the sorting moved from bottom to top, which ensured its vigorous mixing with coal.

In modern technologies, sorting processing, with certain differences, is carried out both according to the Tula and methods used at pre-revolutionary factories. Crushed active wood coal of BAU-A or DAK grades is used according to GOST 6217-74; when preparing vodka for export, BAU-A brand. (According to the mentioned GOST, BAU-A brand coal is intended for use in distillery production and for adsorption from solutions and aqueous media; DAK brand coal is intended for purification of steam condensate from oil and other impurities.) Since the implementation of these technologies in domestic conditions is difficult and impractical , we will not describe them. We only note that modern technologies for processing sorting with active carbon are described in detail in.

Filtering sorting. The sorting is filtered twice: before and after treatment with active carbon. Quartz sand is used as the main filter material, which at vodka production plants is divided into several fractions based on the size of the sand grains. After fractionation, the sand is thoroughly washed with water, then with 3% hydrochloric acid and again with water. The sand thus treated is loaded into cylindrical drums called sand filters. In the simplest sand drums of old designs (Fig. 46), sand fractions with particle sizes from 1 to 3 mm and from 3.5 to 5 mm and coarse gravel were used.

The filter was a copper cylinder, tinned inside, with a diameter of 0.7 m and a total height of 1 m. The total height of the filter layers was about 0.7 m. The number of filter layers was no more than Si. The cylinder was divided in height into three chambers using removable perforated diaphragms , also made of tinned copper: a) upper - supply; b) medium - boot; c) lower - team. The filter material is placed in the loading chamber in layers. In this case, the lower and upper layers are made of gravel, the intermediate layers are made of sand. The perforated diaphragms were covered with fabric pads made of overcoat cloth, felt or flannel. Sometimes layers of sand and gravel were also separated from each other by spacers made of these materials. To retain the largest particles, a pad of several layers of cotton wool was used, wrapped in gauze and placed in the upper part of the filter. Often, in order to retain the largest coal particles, preliminary

filtering the sorting by passing it under pressure through a glass with a layer of flannel or cloth secured at its bottom.

Direction of movement

Sorting while filtering from top to bottom. The first portions of the screening, passing through the freshly loaded sand and gravel, are somewhat cloudy, so they are sent back to the screening tank. When a crystal clear sorting filtrate begins to come out of the filter, switch the filter from the sorting tank to the finishing one. In the finishing vat, the sorting is refined to the required strength by adding alcohol or carefully filtered water, after which the vodka is bottled.

Modern filters use sand of three fractions with particle sizes: from 1 to 1.5 mm; from 1.5 to 2.0; from 2.0 to 3.0 mm. The fabric is not used by placing layers of sand with different particle sizes on top of each other. In this case, the bottom layer of sand, which has the largest grain sizes, is poured onto a fine-mesh metal mesh mounted on a durable lattice frame. Along with sand filters, monolithic ceramic filters with pore sizes of several tens of microns are used.

Vodka recipes. In a strict sense, vodka should consist only of water and grain rectified ethyl alcohol with a share of the latter 40 vol.%. Even before World War II, no other ingredients, with the exception of baking soda, were allowed in it. According to the regulatory documentation of that time, the content of alkaline substances in terms of drinking soda or vodka of ordinary quality could not exceed 300 mg, due to which it was allowed to add baking soda to the sorting with the missing alkalinity, thereby bringing the alkalinity to the full norm (300 mg/l). For vodkas of improved quality, alkalinity was allowed to be increased to 600 mg/l. Due to the fact that in an alkaline environment the absorption properties of activated carbon are weakened, it was recommended to add soda after treating the sorting with carbon.

Along with this, several more vodka recipes are given in the scientific and technical literature of that time. In particular, in the Technical Encyclopedia, vol. 3, p. 860 - 862, (M.: Sov. Encycl., 1928) when preparing vodka, it is recommended to add 0.3 g of baking soda and 1.6 g of beet sugar for each liter of sorting, which leads to a softening of the harshness of its taste. According to vodka, high-tasting quality is obtained if 25 mg of potassium permanganate, previously dissolved in a small amount of water, and 40 mg of 80% water are added to each liter of sorting.

acetic acid. After half an hour, add 200 mg of baking soda and leave everything for 1 - 2 days, after which the entire mixture is filtered from manganese dioxide. The oxidative effect of potassium permanganate carries with it, like ozone, a certain aging effect. After filtration, there is no manganese in the finished product.

In the post-war period, the range of substances used in the production of vodka expanded significantly. Thus, according to GOST 12712-80, when preparing this or that type of vodka and special vodka, in addition to the previously mentioned alcohol, water and active carbon, the following are used: refined granulated sugar and refined sugar according to GOST 22-78, sodium bicarbonate (baking soda) according to GOST 2156-76; food grade acetic acid according to GOST 6968-76; food grade citric acid according to GOST 908-79; edible lactic acid according to GOST 490-79; hydrochloric acid according to GOST 3118-77; potassium permanganate according to GOST 20490-75; table salt according to GOST 13830-68; distilled glycerin according to GOST 68224-76; natural honey according to GOST 19792-87; skimmed cow's milk powder according to GOST 10970-87; potato starch according to GOST 7699-78; aromatic alcohols obtained from aromatic plant materials and highly purified rectified alcohol, essential oils and some other products. It is clear that some of the named substances, such as, for example, starch, milk and potassium permanganate, are used only for sorting cleaning and are absent from the vodka entering the trade. Along with this, some vodkas, for example, "Pshenichnaya" and "Sibirskaya", are made only from alcohol and water and do not contain additives, with the exception of those that come from coal and are formed during the sorting process. Let us present the technology for adding additives and the recipes of some vodkas.

Thus, according to the recipe of A.S. Egorov and his colleagues, given in, vodka containing 36 mg of NaCl (table salt), 546 mg of NaHC03 (baking soda) and 50 mg of Ca(HCO3)2 in 1 dal has high organoleptic characteristics. According to this recipe, table salt and baking soda in the indicated quantities are added directly to the water, after which the solution is passed through a filter with marble chips. During the filtration process, part of the soda chemically interacts with the marble, resulting in the formation of Ca(HCO3)2. (Marble is a rock, its main component is calcite (CaCO3).) Marble chips with particle sizes of 10 - 20 mm are used. The indicated amount of Ca(HCO3)2 is formed when a solution of soda and table salt in water contacts marble chips for 10 - 20 minutes. Water treated in this way is used to dilute alcohol.

Recipes for vodkas “50%”, “Stolichnaya”, “Extra”, “Vodka”, “Moskovskaya special”, “Ukrainian vodka” and “Prazdnichnaya” are given on the basis of; "Sibirskaya" and "Pshenichnaya" - OST 18-292-76 and OST 18-296-76, respectively; "40%" -

GOST 12714-67, "56%" - GOST 12712-67. Unfortunately, we cannot provide the recipes for other vodkas, since it has a prohibitive stamp on it, and the authors are law-abiding citizens.

Vodka "Stolichnaya" To prepare this vodka, refined granulated sugar is used. For 1 dal of sorting, 20 g of sugar is consumed, which is added to the sorting in the form of syrup.

In industrial conditions, sugar syrup is prepared with a sugar content of 65.8 and 73.2 wt.%, which corresponds to approximately 0.52 and 0.37 liters of water per kilogram of sugar. The technology is carried out as follows. In a container of the required volume, heat the water to 50 - 60 ° C, after which, without stopping the heating, pour the calculated amount of sugar into it with constant stirring and, having completely dissolved it, bring the syrup to a boil. During the boiling process, the heating is reduced or stopped several times and at this time the foam is removed from the surface of the syrup. The cessation of foam formation is a sign that the syrup is ready. After this, the heating is stopped and the syrup is quickly cooled. They try to heat the sugar syrup as quickly as possible, because the syrup turns yellow from a long stay at boiling temperature. "It should be noted that while the sugar syrup is boiling, it should be constantly stirred so that it does not burn or turn yellow. The finished syrup is poured into clean, strong oak barrels or into a tinned metal container, in which it is left to cool. It is best to boil the syrup produced in a boiler (copper) with a steam jacket, heated by steam; the inner surface of the boiler must be well tinned. It is also possible to heat the boiler with a steam coil. Steam heating is convenient in that it is easier to regulate and reduces the risk of burning the syrup. If the plant has a fire furnace under boiler for boiling syrup, the walls of the boiler must be protected from direct contact with the flame by installing safety shields or brickwork with an air gap, or using a water bath for heating."

Vodka "Extra". To prepare this vodka, refined granulated sugar and potassium permanganate are used. For one sorting dal, 25 g of sugar and up to 10 mg of potassium permanganate are consumed. To sort, first add a solution of potassium permanganate, mix, and then add sugar syrup.

Vodka "Vodka". To prepare this vodka, 1 dal of sorting requires 1 g of baking soda (NaHCO3), 0.308 g of edible citric acid and 10 g of refined granulated sugar. Baking soda is introduced directly into the sorter in the form of an aqueous solution. Sugar is introduced into sorting in the form of invert sugar. From the specified amount of citric acid, 0.3 g is added to the sorting in the form of a solution to create a certain acidity, and 0.008 g is used to obtain invert sugar (0.08% by weight of sugar).

Invert sugar is a mixture of equal parts

Glucose and fructose. It is obtained by heating sugar syrup in the presence of citric or hydrochloric acids. Sucrose under these conditions is inverted, that is, a sucrose molecule attaches a water molecule and breaks down into molecules of glucose and fructose: C12H22O11 + H20 = CbHigOb + CbHigOb. sucrose water glucose fructose

Compared to sucrose, invert sugar is less susceptible to crystallization when mixed with aqueous-alcohol solutions, is sweeter and has a larger total mass.

To prepare an invert sugar solution, first prepare sugar syrup at the rate of 1 kg of sugar per 0.52 liters of water using the previously described technology. Having removed the foam from the syrup for the last time, add a 10% aqueous solution of citric acid in an amount of 0.08% citric acid by weight of the processed sugar and, stirring, keep it at 95 - 100 ° C for 2 hours. During this time, about 50 % sucrose. With a longer heating duration and, accordingly, the degree of inversion, the syrup darkens, which is unacceptable in the production of vodka. The inversion is carried out in enamel containers.

Vodka "Moscow Special". To prepare this<эдки используют пищевую соду и уксусную кислоту. Пищевую соду в виде концентрированного раствора ее в сортировке вносят непосредственно в основную порциию сортировки для придания ей мягкости, а также используют с уксусной кислотой для получения уксуснокислого натрия (СНзСОСЖа). В каждом конкретном случае массу соды, которую необходимо внести в сортировку, определяют путем титрования исходной сортировки в лаборатории и выполнения расчетов по формуле

M = (0.084 g/ml) (A2 - Ai), where M is the mass of chemically pure NaHC03, which must be added to each 1 dal of sorting to ensure the required alkalinity; A2 is the required alkalinity of sorting, expressed in ml of 0.1 N HCL solution per 100 ml of sorting; A i is the initial alkalinity of the sort, in ml of 0.1 N HC1 solution per 100 ml of sort.

Example: Let Ai = 1.0 ml, and A2 = 3.0 ml (see Table 57 for the requirements for the alkalinity of Moskovskaya Special vodka). Thin M = 0.84 g/ml x (3.0 ml - 1.0 ml) = 1.68 g of baking soda per 1 dal of sorting. A weighed amount of soda is first thoroughly mixed with a small amount of sorting, then poured into the main portion of sorting and also mixed thoroughly.

Titration (determination of alkalinity) of sorting is carried out as follows. 100 ml of sorting is poured into a conical flask made of unpainted chemical-resistant glass with a capacity of 250 - 500 ml, two drops of methyl red solution are added to it, shaken, after which a 0.1 N HC1 solution is gradually added with constant shaking. The titration is completed when the color of the screen changes from yellow to pink. The number of milliliters of HC1 solution used for titration is a measure of the alkalinity of the sorting

|

Table 57. Requirements for physical and chemical parameters of vodka |

||||||||||

|

Indicator name |

Standards for vodkas made from alcohol for domestic consumption |

Standards for vodkas made from alcohol for export |

||||||||

|

Highest purification |

Highest purification |

"Extra" |

||||||||

|

"Russian", "Extra", "Starorusskaya vodka" |

"Wheat" |

"Sibirskaya" |

"Stolichnaya" |

"Moscow special" |

"Posolskaya" |

"Golden Ring", "Golden Gate" |

Special vodkas |

|||

|

Fortress, % |

||||||||||

|

Alkali - volume of slurry acid with (HC1) - 0.1 mol/dm3, used for titration of 100 ml of vodka, cm, no more |

||||||||||

|

Mass concentration of aldehydes in terms of acetic acid in 1 dm of anhydrous alcohol, mg, no more |

||||||||||

|

Mass concentration of fusel oil in terms of a mixture of isoamyl and isobutyl alcohols (3:1) in 1 dm3 of anhydrous alcohol, mg, no more |

||||||||||

|

Mass concentration of esters in terms of ethyl acetate in 1 dm of anhydrous alcohol, mg, no more |

||||||||||

|

Volume fraction of methyl alcohol in terms of anhydrous alcohol, %, no more |

|

(Table 58. Requirements for physical and chemical parameters of vodka

|

(Ai value). We would like to draw the reader's attention to the fact that the given titration method and formula are suitable only for sorting with initially neutral or alkaline properties, which is what takes place in the industrial production of vodka (alcohol has slightly acidic and water has alkaline properties). A solution of methyl red is prepared by dissolving 1 g of the drug when heated in an aqueous-alcohol solution consisting of 300 ml of ethyl alcohol and 200 ml of water.

A solution of sodium acetate is prepared by neutralizing acetic acid with baking soda. According to regulatory requirements, 0.4 ml of 80% acetic acid is consumed per 1 dal of sorting. In order to obtain sodium acetate, the appropriate amount of 80% acetic acid is placed in a tin-plated or enamel container, diluted with 8-10 times the volume of softened water, and to this solution, with constant stirring with a wooden stirrer, baking soda is added in small portions until a solution with neutral properties is obtained. After this, the aqueous solution of CH3SOZH is poured into the sorter and mixed thoroughly.

Vodkas “40%”, “50%”, “56%”, “Sibirskaya” and “Wheat”. To prepare these vodkas, only alcohol and water are used. At the same time, water for Sibirskaya and Pshenichnaya vodkas is treated with active carbon and filtered before mixing with alcohol.

Special vodka "Ukrainian vodka". To prepare this vodka, use 40 g of honey per dal of sorting. Preference is given to linden honey. Honey is introduced into sorting in the form of its solution in vodka or sorting, calculated at the rate of 1 g of honey per 10 ml of liquid. In order to remove mechanical particles and colloidal substances present in honey, before adding it to the sorting, the honey solution is carefully filtered through filter cardboard according to GOST 12290-89.

Special vodka "Festive". To prepare this vodka, use (from the calculation for 1 dal of sorting): baking soda - 2 g, sugar - 2 g, citric acid - 0.8 g.

Solutions of sugar, invert sugar, baking soda and potassium permanganate are added to the sorting before it is processed with active carbon; honey, glycerin, essential oils and aromatic alcohols after its treatment with active carbon, since the latter partially absorbs these substances.

Vodka quality. Determined organoleptically based on tasting and analytically through laboratory tests. At the same time, the quality requirements for vodkas produced for domestic consumption are set by GOST 12712-80, for export - GOST 27907-88.

Organoleptic indicators of vodka are: a) appearance; b) color; c) taste and aroma. According to these GOSTs, the requirements for the organoleptic characteristics of vodkas produced for domestic consumption and exported are identical: vodka must be a transparent liquid without foreign inclusions or sediment; should be colorless; have the taste and aroma characteristic of this type of vodka, and do not have any foreign taste or aroma. In practice, organoleptic indicators are assessed on a ten-point scale. The highest score - 10 points - is assigned to vodka that has impeccable transparency and crystal luster (2 points); not having a sweet, pungent or bitter taste (4 points); without the smell of alcohol and other foreign substances and with an aroma characteristic of vodka of this type (4 points).

Analytical (physical and chemical) requirements for vodkas produced for domestic consumption (GOST 12712-80) and for export (GOST 27907-88) are given in Table. 57.

Later, in GOST 12712-80, in accordance with change No. 4 of 07/04/86, in the table specifying the requirements for the physical and chemical indicators of vodka, the word “Extra” was excluded from the column “Norm for vodkas from highly purified alcohol”, and in accordance with Amendment No. 5 dated November 12, 1991, the requirements for the physical and chemical characteristics of vodka are set out in a new edition (see Table 58).

Vodkas have a certain shelf life. According to GOST 12712-80, the guaranteed shelf life for vodka is 12 months, vodka intended for the USSR Ministry of Defense is 18 months, and special vodka is 6 months from the date of bottling.

Vodka is a strong alcoholic beverage. (According to GOST 20001-74: liqueurs and vodka products are alcoholic drinks with a strength of 12 - 60%, prepared by mixing semi-finished products with rectified alcohol; strong alcoholic drinks are alcoholic drinks with a strength of 30% and above). However, as we say in Kyiv, “Each drink has its own buzz.” Therefore, along with vodka, the industry produces other alcoholic drinks based on rectified ethyl alcohol: liqueurs, creams, liqueurs, tinctures, balms, etc. These drinks have different strengths (from 12 to 60°), and, unlike vodka, contain significant amounts of sugar, food coloring, acids, aromatics and other substances. The technologies for producing and formulating such drinks, as well as cognac, whiskey and gin, will be presented in the second part of this book.

There are no substances, including ethyl alcohol, with 100% content of the main component in nature, since any substance, even the purest, contains a certain amount of impurities. Therefore, for example, the terms “100% alcohol” or “100% acid” do not correspond to the real substance, but are used to facilitate calculations and records. The industry produces, in limited quantities, so-called absolute alcohol, containing at least 99.8 vol.% ethyl alcohol, and water as the main impurity. In laboratories, using certain chemicals, rectified and absolute alcohols produce alcohol with a negligible water content. In modern scientific and technical literature, instead of the term “100% alcohol,” the term “anhydrous alcohol” is more often used.

Detailed tables for converting metric units into Russian and Russian into metric are given in the “Encyclopedic Dictionary” (vol. 9) of Brockhaus-Efron. - St. Petersburg: TypogrAkts. Society "Publishing", Brockhaus-Efron, 1900.

This corresponds to 1 kg of flour per 4.2 liters of water.

This corresponds to 1 kg of flour per 5.4 liters of water.

Baltic Provinces - German name for the Baltic region

Before the invention of alcohol meters, the alcohol content of wine was determined by burning off the alcohol. For this purpose, a certain volume of wine was placed in a metal glass and set on fire. It was believed that the difference in the volume of wine before and after the end of combustion corresponded to the volume of alcohol present in it. It is clear that this method was inaccurate and always gave an overestimated alcohol content, since part of the water evaporated during the combustion process. If the burnt-out alcohol was half or two-thirds of the volume, then in Russia such wine was called “polugar” or “two-thirds gar,” respectively.

To me, as a person who drank deeply in the past, it became interesting not only in terms of the nostalgic component, but simply in the opportunity to highlight a not-so-dark period of our history, our recent past, which was presented by our partners exclusively as a hat with earflaps, vodka and a balalaika .

When I was young, I heard that in New York alone you can buy about two thousand varieties of whiskey. This surprised me greatly. Well, how can this be, when the unforgettable Ostap Bender, the one who knew four hundred relatively honest ways of taking money, knew one hundred and fifty ways of making moonshine, even from a stool, and he was, one might say, an expert in this matter. It was he who discovered and sold for only two hundred Soviet full rubles, the secrets of the homeland to two citizens of the city of Chicago, exhausted by Prohibition, or as they are now called, our partners, these recipes, after which the era of moonshine in the USA acquired truly epic proportions..... From several recipes with the help of enterprising Americans, the quality of simple Russian pervacha TM has turned into quantity, namely two thousand varieties of whiskey in one city......

In order not to be unfounded, here are some recipes, here are some recipes, from the lost notebook of the Great Combinator

MOONHOON SUGAR

Take 6 kg of sugar, 200 g of yeast, pour in 30 liters of warm water and mix well, add a bunch of dry dill and currant leaves for flavor.

Infuse in a warm place for 6-7 days, then distill.

Yield: 6 liters.

It is widely believed that 1 kg of sugar produces 1 liter of moonshine. If you use effective devices, 10 liters of good moonshine is obtained from 7 kg of sugar.

In this case, excess sugar is not required, since it will still go to waste.

MOONHOON STARCH

Take 10 kg of starch, dilute with 20 liters of water and brew like jelly, add 500 g of yeast and 1 kg of sugar.

Leave for 3-5 days. Then distill.

Yield: 11 liters.

No, of course, there were other attempts to export batches of moonshine from Odessa to overseas democracy, but they ended in failure....and that’s not what I’m talking about.....

The 80s... What nostalgia for this time is experienced by everyone who saw it. Who remembers. Who knows what I'll talk about today.

Before turning directly to the subject of our today's memories, I really want to look there at least with one eye... Into the past, at the time when... But this WHEN is different for everyone.

But the city was completely different. And in this other city everything was different. Although he is certainly ours, modern, he seems to be from a parallel reality. What are these types worth:

Having inhaled the air of a parallel world, it’s time for us to feel its taste... Much water has flown under the bridge since then, they have invariably tried to fake the taste - but it remains. The same, and forever. And so that our excursion does not look too superficial, I am ready to provide tastes with a little “spice” of history. So, let's begin:

In 1938, the recipe and trademark were registered in the USSR vodka "Stolichnaya". Vodka began to be produced only a few years later, in 1941, and the first bottle of Stolichnaya was released in Leningrad.

Since 1971, vodka began to be sold in the USA. The American company PepsiCo (we all know Pepsi-Cola!) received the rights to distribute vodka in exchange for the right to build a plant for the production of carbonated drinks in Novorossiysk. In America, our “Stolichnaya” received the stable name Stoli.

In post-Soviet times, there was, and is still happening, a terrible confusion with the owners of the Stolichnaya brand. At the moment, this vodka is boycotted by gays and lesbians in the USA and England (as a Russian product), and vodka is produced in Latvia. There is no official production of this brand of Russian vodka in Russia.

Moscow special vodka or just Moscow vodka

is a national brand of Russian vodka, introduced in 1894 by the Russian State Vodka Monopoly. Its production was stopped (along with other spirits) with the introduction of a ban in Russia after the outbreak of the First World War. The brand was reinstated in the Soviet Union in 1925. Throughout its history, the Moskovskaya bottle has been characterized by a green label.

In addition to water and alcohol, the standard recipe for Moscow includes small amounts of baking soda and acetic acid. Moskovskaya is the only variety of Soviet vodka produced from grain alcohol.

Vodka "Wheat"

The history of Wheat Vodka dates back to the 70s of the 20th century. In fact, this is a new brand developed for domestic Soviet consumption. It was with this vodka, according to Leonid Parfenov, that a screw cap was first used, and only with this vodka did the understanding begin that you don’t have to finish the bottle, leaving it “for later.”

The label of this vodka was decorated with a picture, according to the same Leonid Parfenov, “simply copied from an ABC book.” The same native open spaces, the same fields, stacks and village... Everything is completely in the Russian style.

Siberian vodka

It appeared, like Pshenichnaya, in the 70s. It was distinguished by its increased strength compared to the “Pshenichnaya” one and, like the “Pshenichnaya” one, had a screw cap. Originally intended for domestic consumption, it found excellent markets overseas. The traditional design with three is to blame for this, the name is associated with the wild Russian region, or what else - now it’s impossible to say for sure. However, it was at Sibirskaya that the technology for purifying vodka with activated carbon was first tested and then put into mass production.

Kubanskaya

Although it was officially called vodka, it was always a bitters. At first the label said “Russian vodka”, but then, in the process of development, the words about vodka disappeared. And “Bitters” appeared.

Russian

Let's just say it was a mass model. This vodka had a sharp and unpleasant taste and smell, despite all attempts to flavor the product with cinnamon. But it was produced everywhere; each republic had its own “Russian”. What’s interesting is that it was also exported. The brand became dilapidated and dilapidated, deteriorating. but... But the reincarnation of Russian vodka is currently taking place. And this is not the fault of alcohol producers. The Olympics in Sochi is the main catalyst. I won’t say anything more, I suggest you look at the photo:

So we remembered the tastes from the old world. The forbidden doors opened slightly for a second, but alas, it’s time for us to move on. Where to go?

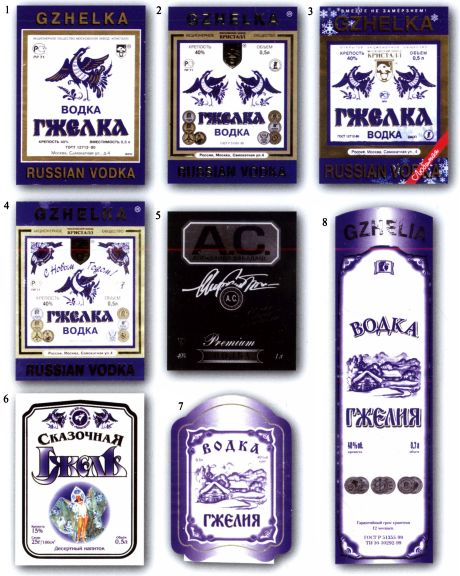

1. Initially, it was planned to depict knights on the “Russkaya” label

2. Double label with a necklace from a souvenir bottle

3. Classic “Russian” label - the so-called “heroic”

4. The second classic option. This label has been issued unchanged for a quarter of a century.

5. “Russian” - “two stripes”

6. A label with a printing defect was also useful

7. Label from Gaidar’s times - without medals and indication of the vodka manufacturer

8. Label for a 0.33 Pepsi bottle

The first vodka in the top row is produced by Asfalt JSC!

Post-Soviet “Russian” in all its diversity

1. “Moscow special” - one of the first options

2. First medal: Bern, 1954

3. Classic “Moscow Special” label

4. “Moscow Special” - a rare Central Asian version of the 1960s

5–7. Export options

8. When label printing did not keep up with prices, they put a stamp

9. Another classic label option. Vodka with such labels was produced in all Soviet republics

1. “Moscow Special” from a special series released for the 850th anniversary of Moscow

2. Label from the last year of the existence of the USSR. Due to the lack of normal paper, it was printed almost on blotting paper.

3–8. Post-Soviet labels. At first the label was recognizable, then new design solutions came

9. “Mordovian special”... An example of mimicry of a famous brand

1. Classic “Wheat” label

2. A special “Wheat” was produced for restaurants

3–6. Post-Soviet metamorphoses of Pshenichnaya

7–9. Vodka based on the idea of “Wheat”

1. Initial - strict - version of “Stolichnaya”

2. Classic label version.

3. Option with “two stripes” - and even with a quality mark!

4. Special message for Aeroflot

5–8. "Stolichnaya" for export

9. “Stolichnaya” from a special series released for the 850th anniversary of Moscow

Post-Soviet variations on the theme “Stolichnaya”

1. Classic “Posolskaya” label

2–7. Post-Soviet labels, including those with “two stripes”, which were absent on the Soviet “Posolskaya”

8. Ladies' "Posolskaya"?

9. This, of course, is not “Posolskaya”, and yet...

1–2. “Golden Ring” is one of the most successful Soviet labels

Label and back label

3–7. Modern label options

8. Vodka “Podmoskovnaya” - mimicry of the “Golden Ring”

1–6. Soviet variants of the Zubrovka

7–9. Modern "Zubrovka"

1–3. Starkey labels from the 1960s and 1970s

4–5. "Stark" in the 1970s-1980s

6. Stark 1990s

7–9. Post-Soviet vodkas “under Starka”

1. One of the first variants of “Kubanskaya”

2. Classic label

3–4. Soviet "Cossack" drinks

5–6. Post-Soviet vodkas

7–9. Soviet versions of "Lemon". Each republic issued its own

1. All-Union version of “Lemon”

2–8. Post-Soviet “Lemon” - both classic 40 degrees, and “ladies” 28 degrees, and 63-degree infusion...

1–6. Soviet "Pepper"

7–9. Modern varieties of “Pepper” with enhanced strength. In fact, this is no longer “Pepper”...

1–2. Soviet "Pertsovka"

3–4. Post-Soviet “Pertsovki” in Russian and Moldavian versions

5–9. Modern versions of tinctures of the “Pepper” type

1. Classic “Hunting” label

2. Classic “Hunting” label. Export version

3–5. "Hunting" 1960-1970s

6. Post-Soviet Arkhangelsk “Okhotnichya”

7–9. Variations on the theme of hunting

More hunting variations...

1–4. 50% vodka

5–9. "Drinking alcohol." Labels 1960-1980s

1–6. “Drinking alcohol” from the time of perestroika

7. Forty-degree “alcohol”

8–9. Variants of alcohol "Royal"

10. American spirit

1. 56-proof vodka. Thanks to the label, it was popularly called “Tuchka”

2. Vodka for 3.62. The legendary "Crankshaft"

3. "Andropovka"

4–5. Simultaneously with “Kolenval”, a new vodka of higher quality was released - “Extra” at 4.12

6. Label from “Raiska” from a bottle with a capacity of 0.33

7–9. Vodkas "Yubileinaya" and "Strong" trace their history back to 1937

1–5. Transformations of the “Moscow Special” in the post-Soviet space

6–9. Metamorphoses of “Russian”

1. Ukrainian vodka “Rosiyska” (that is, “Russian”) with a knight at the crossroads...

2–5. "Stolichnaya" in post-Soviet Ukraine and Belarus

6–9. "Wheat" in Ukraine and Belarus

1–2. Ukrainian vodka from Soviet times. In the export version it is designated as “Russian vodka”

3–6. Post-Soviet vodka

7–8. Post-Soviet Belarusian vodkas

9. Export version of the “Original Belarusian”

1. Estonian vodka “Viru Valge” from Soviet times

2–4. Lithuanian vodkas from Soviet times

5. “Lietuvishka Kristadine” from the 1960s

6–7. "Lietuvishka Kristadine" 1970-1980s. Label and back label

8. “Lietuvishka kristadine”… made in Crimea. 1990s

1–2. Latvian vodka "Crystal Dzidrais" from Soviet times

3. “Crystal Dzidrice” made in Kyrgyzstan

4. Ukrainian “Russian vodka” “Crystal Dzidrice”

5–6. Post-Soviet - real, Latvian - "Crystal Dzidrais"

7. Post-Soviet transformation of “Crystal Dzidrais” into Uzbek arak

8. “Crystal Dzidrais”, bottled in Rostov-on-Don